Product Details

Panel Joining Machine Operation Process:

Panel Joining Machine Operation Process

Shuipo Welding & Cutting - Automatic Plate Butt Welding Machine

On-site Application at CIMC Dongyue

On-site Application by Indonesian Customer

On-site Application of Equipment in Indonesia

Conveying and Discharging Device

Automatic Welding Torch Device for Plate Butt Welding

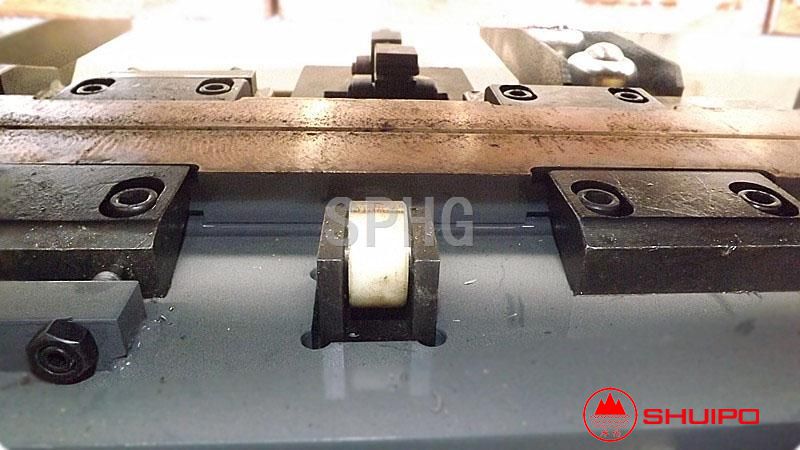

Welding Centering Device for Plate Machine

Ejecting Device for Automatic Plate Welding Machine

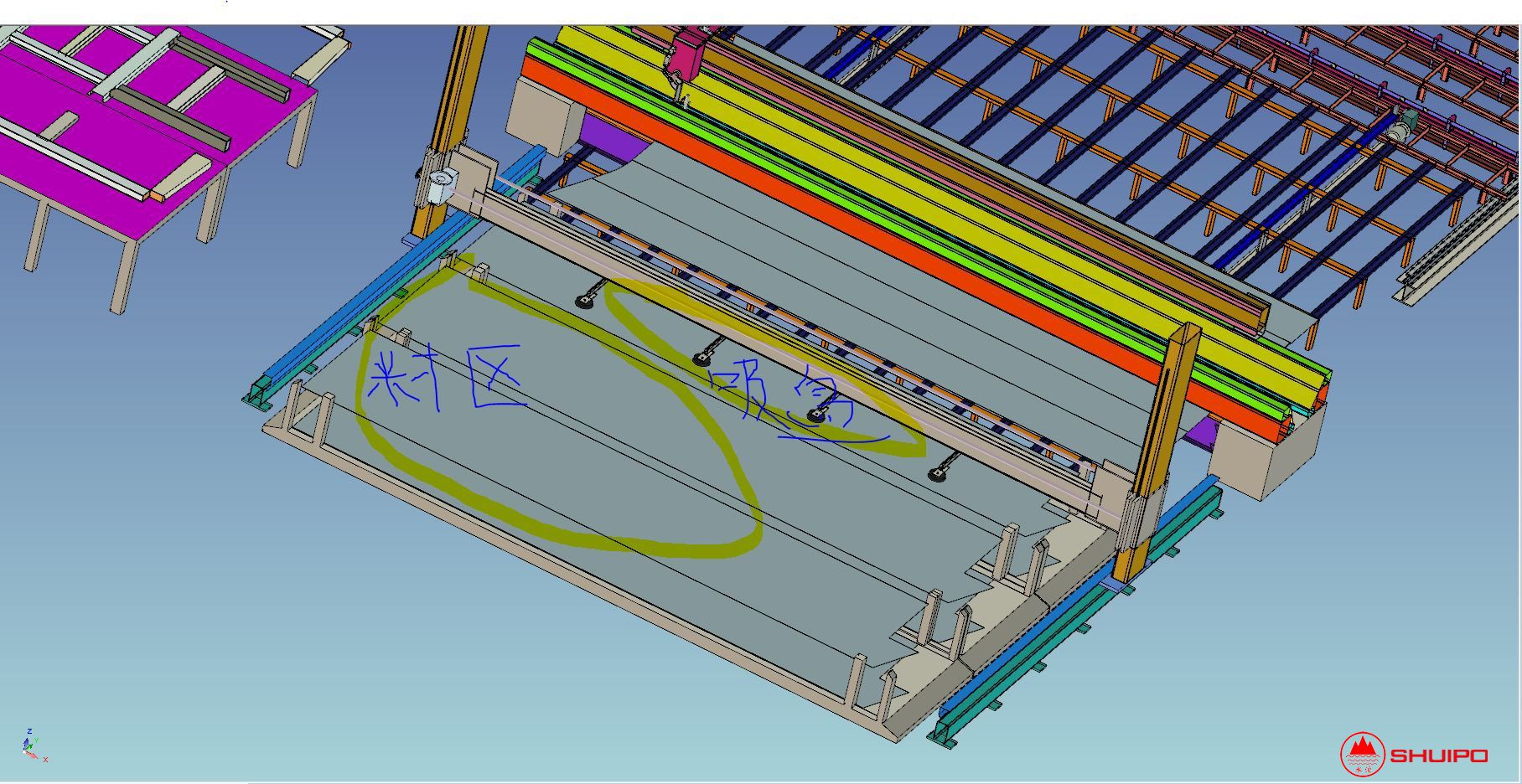

Automatic Loading System

Product Introduction:

The panel joining machine (automatic plate butt welding machine) clamps the two workpieces to be welded on a special forming groove plate through a piano-key type pressing device. When starting welding, the welding torch is moved to the target position, and a motor drives the water-cooled welding torch to travel, welding the two workpieces together. The welding seam adopts single-sided welding with double-sided forming, featuring small welding deformation. The front and back welds are smooth, neat, and aesthetically pleasing with smooth transitions. The deviation in straightness of the front and back welds within the full length does not exceed ±1.5 mm, the front reinforcement does not exceed 2 mm, the back reinforcement is not less than 1 mm, and the weld width is 5-12 mm.

The mechanical part is equipped with various basic functional components for users, mainly including the bed body, piano-key type pressing device, crossbeam, platform, central positioning device, pneumatic system, welding carriage, etc. Cooperating with the wire feeder, welding power source, and electrical control system, it can complete automatic welding of steel plates. The bed body has sufficient rigidity to withstand the pressing force, and the piano-key type pressing device clamps the workpiece with uniform pressing force. The welding speed is driven by a DC motor to achieve stepless speed regulation, which is convenient for speed adjustment.

※The above is for reference only,subject to the contract.