Product Details

The intelligent production line for aluminum alloy tanks is an intelligent production solution for the manufacturing process of tank trucks. With this solution, a series of intelligent technological processes can be achieved, including the automation of the transfer of large workpieces of tank trucks, the unmanned operation of plate - splicing and welding, the standardization of one - time tank forming, and the automation of head welding.

Plate Splicing Machine-9500(TIG)

Plate Splicing Machine-8500(TIG)With Support Device

METAL SHEET TURNING MACHINE

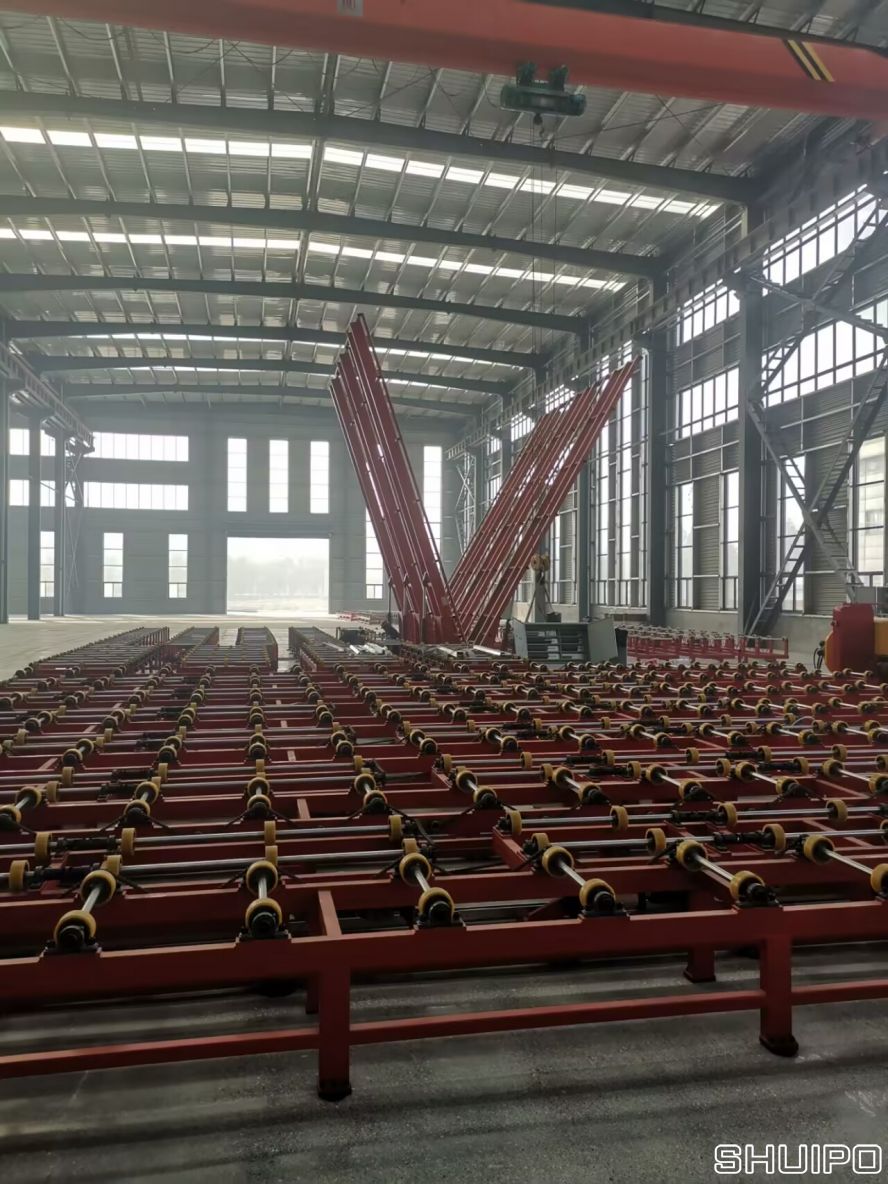

Automatic Feeding Table for Plate Rolling Machine

Long - axis Roller Frame - 12.5m (Hydraulic Boom)

Long-axis Roller Frame - 12.5m (Pneumatic Clamping Gantry)

AUTO WELDING MACHINE FOR TANK(TIG)

Rotating Body - Single - drive with Fixture

Special-shaped Tank Longitudinal Seam Welding Machine

Robot Welding Workstation for Tank Attachments

Tank Transfer AGV

In the aluminum alloy tank production line, new automated production technologies have been introduced, with full consideration given to the intelligence and high efficiency of the production line. Through an innovative automatic control system, seamless connection and automated control among all links of the production line are achieved, which greatly improves production efficiency and product quality.

※The above is for reference only,subject to the contract.